KEMEL manufactures the EVK type water seal. The EVK type seal has many benefits for owners and operators of vessels with water lubricated shafting. The EVK type seal is the easiest of the seals on the market for installation and operation. The seal does not wear the propeller shaft sleeve.

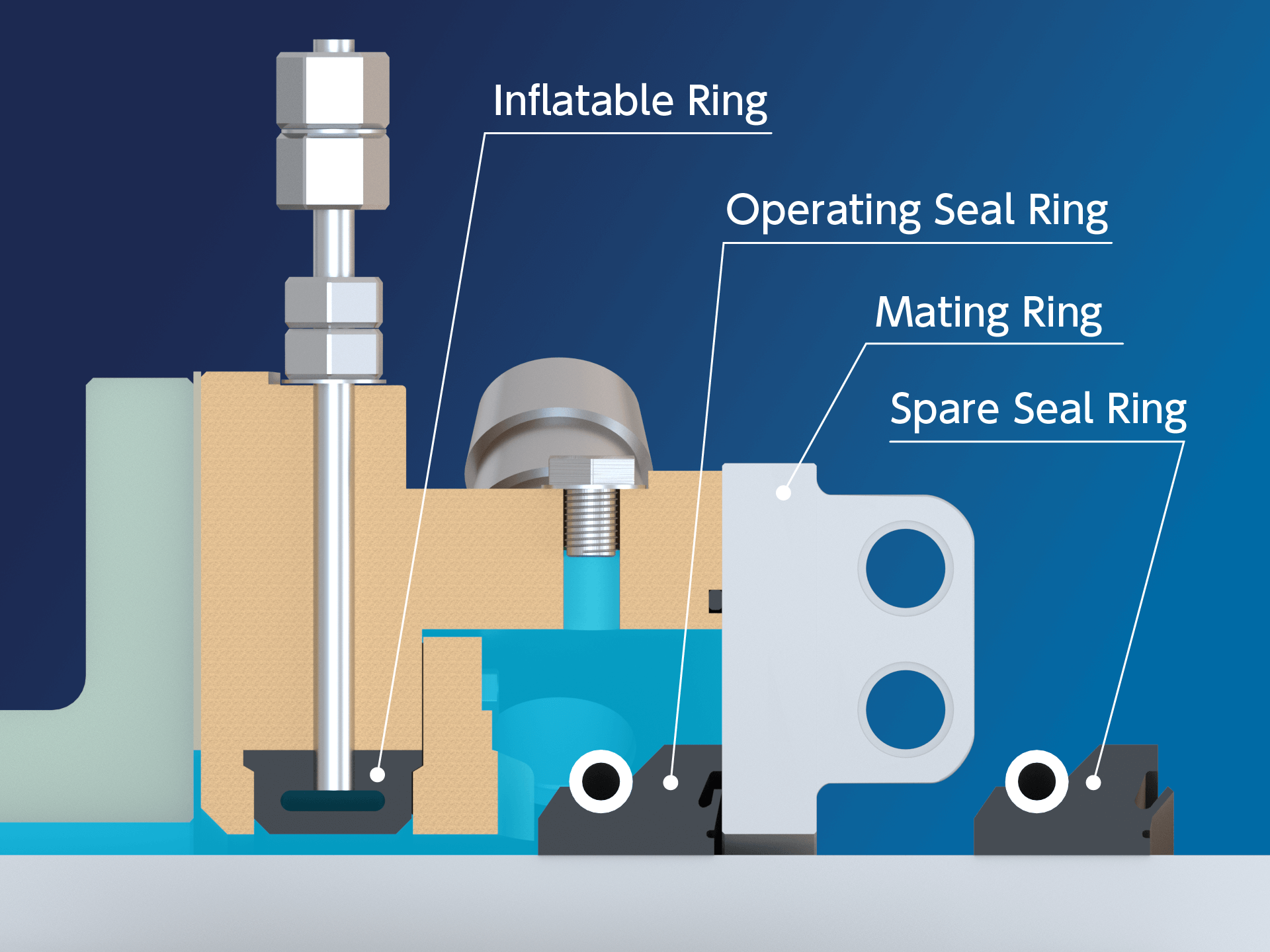

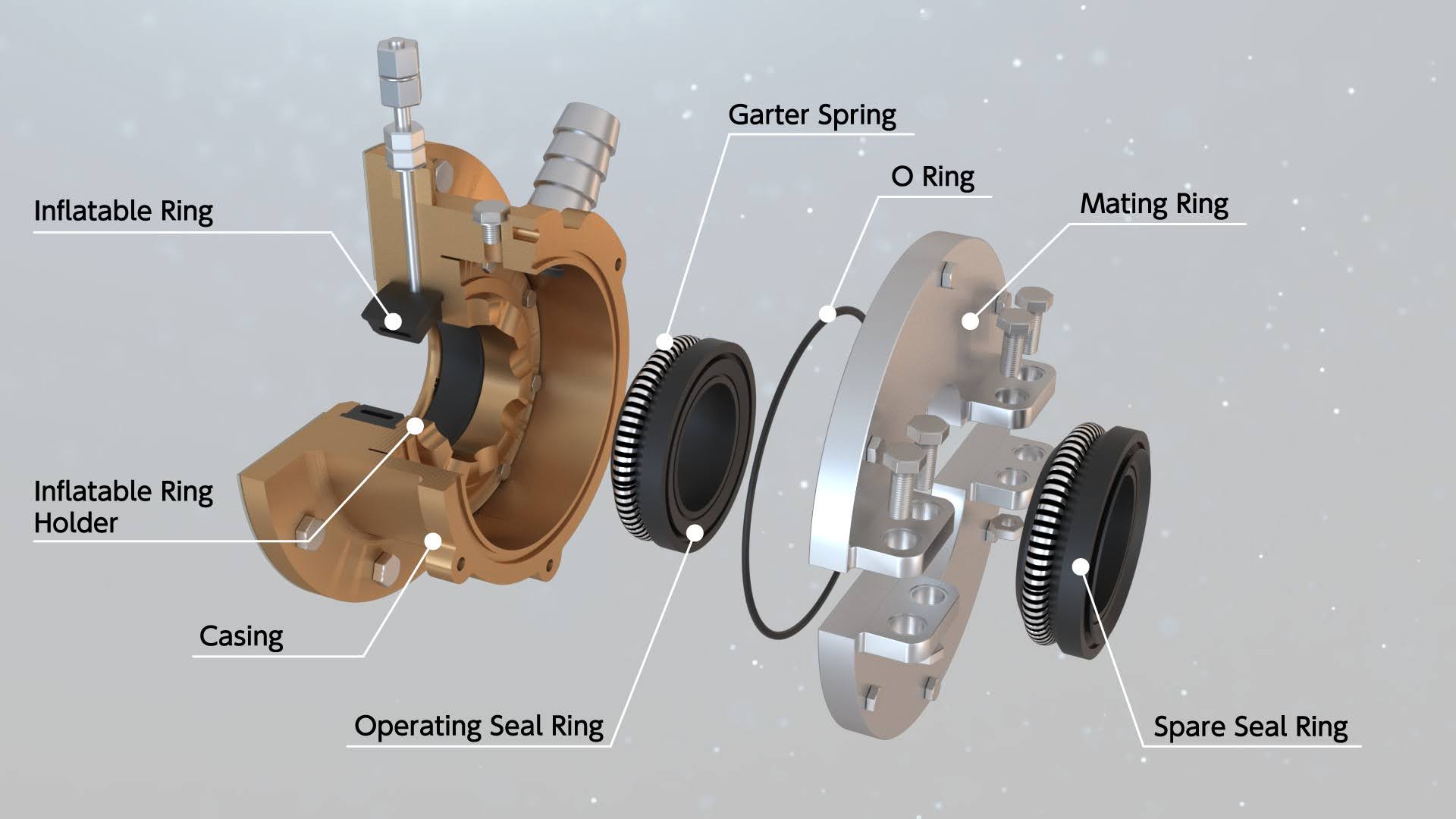

The design of the KEMEL EVK type seal is very simple. Since it is a face type seal consisting of the seal ring and the mating ring, it flexibly copes with complicated vibration and shaft deflection and shows excellent sealing performance. All seal assemblies are supplied with an active seal and a spare seal which is installed on the shaft ready for installation.

A compact, high performance water lubricated seal having excellent vibration resistance and sealing performance.

Features

- ●Excellent Sealing Performance with Shaft Vibration Resistance

Since it is an end face type seal consisting of the seal ring and the mating ring, it flexibly copes with complicated vibration and shaft deflection and shows excellent sealing performance. - ●No wear of shaft sleeve

The seal ring rotates together with the shaft sleeve and therefore, there is not wear of the shaft sleeve. “Eagle Paint” is provided on the surface of the shaft sleeve to prevent corrosion. - ●Easy Replacement of Parts

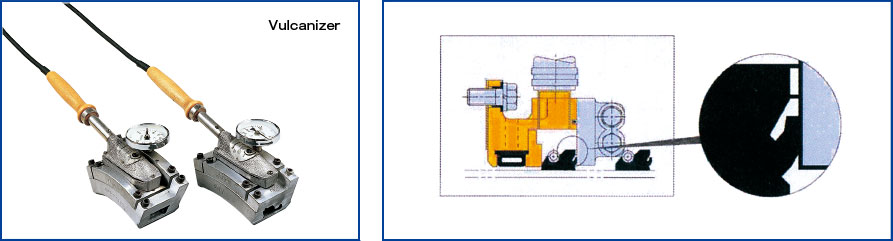

The seal ring and the inflatable ring can be easily bonded over the shaft by the vulcanizer. By working the inflatable ring, inspection and replacement of the seals ring on the sea can be easily done. - ●Maintenance Saving

The sealing faces of the seal ring and the mating ring are lubricated by sea water coming through the notches of the seal ring, and therefore daily maintenance will not be required.

- Standard Dimension

- CASING : Non SPILIT type or SPLIT Type

| Size | Shaft Sleeve Dia A | B | P | C | E | F | G | L1 | L2 | L3 | Lf | L | T1 | T2 | T3 | Z | U | α | β | Mass(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 110 | 101~120 | 270 | 240 | 148 | 240 | 1-20A | 220 | 122 | 74 | 103 | 54 | 170 | 15 | 19 | 18 | 6-M12×35 | 16 | 30 | 30 | 20 |

| 130 | 121~140 | 290 | 260 | 168 | 260 | 1-20A | 220 | 122 | 74 | 103 | 54 | 170 | 15 | 19 | 18 | 6-M12×35 | 16 | 30 | 30 | 22 |

| 150 | 141~160 | 310 | 280 | 188 | 280 | 1-20A | 220 | 122 | 74 | 103 | 54 | 170 | 15 | 19 | 18 | 8-M12×35 | 16 | 45 | 22.5 | 25 |

| 170 | 161~180 | 330 | 300 | 208 | 300 | 1-20A | 220 | 122 | 74 | 103 | 54 | 170 | 15 | 19 | 18 | 8-M12×35 | 16 | 45 | 22.5 | 27 |

| 190 | 181~200 | 350 | 320 | 228 | 320 | 1-20A | 220 | 122 | 74 | 103 | 54 | 170 | 15 | 19 | 18 | 8-M12×35 | 16 | 45 | 22.5 | 29 |

| 210 | 201~220 | 385 | 350 | 248 | 345 | 1-25A | 320 | 122 | 74 | 104 | 51 | 170 | 15 | 19 | 18 | 6-M16×40 | 20 | 40 | 30 | 34 |

| 230 | 221~240 | 405 | 370 | 271 | 375 | 1-25A | 320 | 139 | 91 | 121 | 68 | 190 | 15 | 25 | 18 | 6-M16×40 | 20 | 40 | 30 | 42 |

| 250 | 241~260 | 425 | 390 | 291 | 395 | 1-25A | 320 | 139 | 91 | 121 | 68 | 190 | 15 | 25 | 18 | 6-M16×40 | 20 | 40 | 30 | 45 |

| 270 | 261~270 | 445 | 410 | 311 | 415 | 1-25A | 320 | 139 | 91 | 121 | 68 | 190 | 15 | 25 | 18 | 8-M16×40 | 20 | 45 | 22.5 | 49 |

| 〃 | 271~280 | 〃 | 〃 | 〃 | 〃 | 2-25A | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 | 〃 |

| 290 | 281~300 | 465 | 430 | 331 | 435 | 2-25A | 320 | 139 | 91 | 121 | 68 | 190 | 15 | 25 | 18 | 8-M16×40 | 20 | 45 | 22.5 | 52 |

| 310 | 301~320 | 485 | 450 | 351 | 455 | 2-25A | 320 | 139 | 91 | 121 | 68 | 190 | 15 | 25 | 18 | 8-M16×40 | 20 | 45 | 22.5 | 54 |

| 330 | 321~340 | 520 | 480 | 371 | 475 | 2-25A | 320 | 141 | 93 | 123 | 70 | 190 | 18 | 26 | 18 | 8-M20×50 | 26 | 45 | 22.5 | 63 |

| 350 | 341~360 | 540 | 500 | 391 | 495 | 2-25A | 320 | 141 | 93 | 123 | 70 | 190 | 18 | 26 | 18 | 8-M20×50 | 26 | 45 | 22.5 | 65 |

| 370 | 361~380 | 560 | 520 | 411 | 515 | 2-25A | 320 | 141 | 93 | 123 | 70 | 190 | 18 | 26 | 18 | 8-M20×50 | 26 | 45 | 22.5 | 68 |

| 390 | 381~400 | 580 | 540 | 431 | 535 | 2-25A | 320 | 141 | 93 | 123 | 70 | 190 | 18 | 26 | 18 | 8-M20×50 | 26 | 45 | 22.5 | 71 |

| 410 | 401~420 | 640 | 580 | 515 | 580 | 2-32A | 135 | 167 | 106 | 145 | 72 | 215 | 22 | 29 | 25 | 8-M24×60 | 31 | 45 | 22.5 | 101 |

| 430 | 421~440 | 660 | 600 | 535 | 600 | 2-32A | 135 | 167 | 106 | 145 | 72 | 215 | 22 | 29 | 25 | 8-M24×60 | 31 | 45 | 22.5 | 110 |

| 450 | 441~460 | 680 | 620 | 555 | 620 | 2-32A | 135 | 167 | 106 | 145 | 72 | 215 | 22 | 29 | 25 | 8-M24×60 | 31 | 45 | 22.5 | 118 |

| 470 | 461~480 | 700 | 640 | 575 | 640 | 2-32A | 135 | 167 | 106 | 145 | 72 | 215 | 22 | 29 | 25 | 8-M24×60 | 31 | 45 | 22.5 | 126 |

| 490 | 481~500 | 720 | 660 | 595 | 660 | 2-40A | 135 | 167 | 106 | 145 | 72 | 215 | 22 | 29 | 25 | 8-M24×60 | 31 | 45 | 22.5 | 132 |

| 510 | 501~520 | 760 | 700 | 615 | 680 | 2-40A | 135 | 186 | 125 | 164 | 82 | 230 | 30 | 34 | 25 | 12-M24×70 | 33 | 30 | 15 | 161 |

| 530 | 521~540 | 780 | 720 | 635 | 700 | 2-40A | 135 | 186 | 125 | 164 | 82 | 230 | 30 | 34 | 25 | 12-M24×70 | 33 | 30 | 15 | 167 |

| 550 | 541~560 | 800 | 740 | 655 | 720 | 2-40A | 135 | 186 | 125 | 164 | 82 | 230 | 30 | 34 | 25 | 12-M24×70 | 33 | 30 | 15 | 180 |

| 570 | 561~580 | 820 | 760 | 675 | 740 | 2-40A | 135 | 186 | 125 | 164 | 82 | 230 | 30 | 34 | 25 | 12-M24×70 | 33 | 30 | 15 | 190 |

| 590 | 581~600 | 840 | 780 | 695 | 760 | 2-40A | 135 | 186 | 125 | 164 | 82 | 230 | 30 | 34 | 25 | 12-M24×70 | 33 | 30 | 15 | 200 |

| 610 | 601~620 | 860 | 800 | 715 | 780 | 2-40A | 135 | 187 | 125 | 164 | 82 | 230 | 30 | 34 | 25 | 12-M24×70 | 33 | 30 | 15 | 210 |

| 630 | 621~640 | 880 | 820 | 735 | 800 | 2-40A | 135 | 187 | 125 | 164 | 82 | 230 | 30 | 34 | 25 | 12-M24×70 | 33 | 30 | 15 | 220 |

| 650 | 641~660 | 900 | 840 | 755 | 820 | 2-40A | 135 | 160 | 125 | 175 | 82 | 230 | 30 | 34 | 35 | 12-M24×70 | 33 | 30 | 15 | 240 |

| 670 | 661~680 | 950 | 870 | 775 | 850 | 2-40A | 150 | 162 | 127 | 177 | 84 | 230 | 30 | 36 | 35 | 12-M30×80 | 42 | 30 | 15 | 275 |

| 690 | 681~700 | 970 | 890 | 795 | 870 | 2-40A | 150 | 162 | 127 | 177 | 84 | 230 | 30 | 36 | 35 | 12-M30×80 | 42 | 30 | 15 | 282 |

| 710 | 701~720 | 990 | 910 | 815 | 890 | 2-40A | 150 | 162 | 127 | 177 | 84 | 230 | 30 | 36 | 35 | 12-M30×80 | 42 | 30 | 15 | 289 |

| 730 | 721~740 | 1010 | 930 | 835 | 910 | 2-40A | 150 | 162 | 127 | 177 | 84 | 230 | 30 | 36 | 35 | 12-M30×80 | 42 | 30 | 15 | 296 |

| 750 | 741~760 | 1030 | 950 | 855 | 930 | 2-40A | 150 | 162 | 127 | 177 | 84 | 230 | 30 | 36 | 35 | 12-M30×80 | 42 | 30 | 15 | 303 |

| 770 | 761~780 | 1050 | 970 | 875 | 950 | 2-40A | 150 | 162 | 127 | 177 | 84 | 230 | 30 | 36 | 35 | 12-M30×80 | 42 | 30 | 15 | 310 |

| 790 | 781~800 | 1070 | 990 | 895 | 970 | 2-40A | 150 | 162 | 127 | 177 | 84 | 230 | 30 | 36 | 35 | 12-M30×80 | 42 | 30 | 15 | 317 |

※Please note that other non standard size can be manufactured upon requested.

※Longer bolts can be supplied upon request when the bearing flange is fixed between the stern tube and the EVK seal.